The main Estralin activity is production of high-voltage cable 60-220 kV and delivery of cable systems 60-500 kV.

Estralin offers XLPE insulated single core power cables for long-distance power transmission in distribution and transmission networks for application under different conditions.

Completely water-sealed HDPE sheathed cable is used for underground transmission, while for the installation under water Estralin offers cable with additionally applied round wires armour.

Cable with outersheath from flame retardant and halogen free PE composition is used for installation in the cable’s ducts or outdoors.

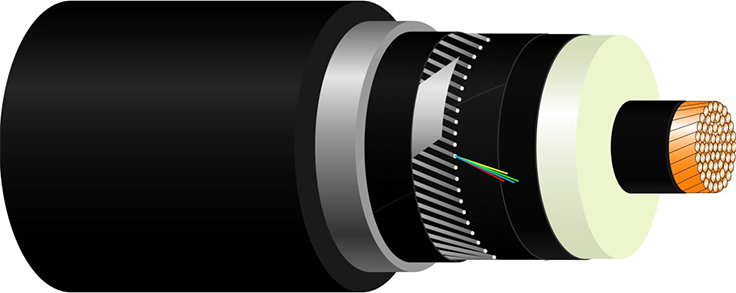

* The conductor is used for the transmission of electric current. The material, shape and cross-section of the conductor defines the current-carrying capacity of the cable line.

* The inner semi-conductive screen provides equal distribution of the electric field at the boundary of the conductor and the insulation.

* XLPE insulation is the main insulating element of 60-500 kV XLPE cables design. Insulation is a layer of XLPE with high dielectric strength. Insulating XLPE shall withstand the effects of electric field both in operational and transient conditions.

* The conductive screen provides equal electric field distribution in cable insulation.

* Optional optical fiber modules (FIMT) can be embedded into the wire screen for cable temperature control purpose.

* Separation layer is made of water-blocking semi-conductive tapes that serve as a moisture barrier. It is required to prevent the moisture spreading if the cable sheath is damaged (longitudinal sealing) as well as to ensure that the outer semi-conductive screen is separated thermally and mechanically from the cable wire screen.

* The main purpose of the wire screen is an equal distribution of potential across the cable insulation and transmission of short-circuit currents.

* Separation layer is a layer of conductive water-blocking tapes that serves as a thermic separator between metal screen and outersheath and a water barrier (longitudinal sealing).

* Longitudinal sealing prevents moisture from entering through the outersheath.

* The outer sheath is required for insulating the wire screen from the ground and protecting the cable from mechanical damage during installation and maintenance as well as from any adverse external effects.

| Cooper conductor | Without marking |

| Aluminum conductor | A |

| Round stranded conductor | RM |

| Segmented conductor | RMS |

| XLPE Insulation | 2X |

| Copper | S |

| Aluminum | SA |

| Longitudinal water sealing | (F) |

| Longitudinal and radial water sealing | (FL) |

| Optical fiber in the screen | LWL |

| Aluminum alloy wires armour | AWA |

| Lead sheath | K |

| PVC sheath | Y |

| HDPE sheath | 2Y |

| Halogen free flame-retardant sheath | H |

* Design and marking of the cable can be changed by the implementation of new solutions.

Marking examples:

A2XS(FL)2Y 1×300RM/50 – 64/110 kV

Estralin pays special attention to product quality control according to the standards of the International Electrotechnical Commission (IEC): IEC 60840 at rated voltage of equipment above 30 kV to 150 kV, IEC 62067 at rated voltage of equipment above 150 to 500 kV.

Determining the compliance of cable parameters and its accessories with the standard and internal quality requirements are carried out in several stages:

Estralin quality control system provides total quality control of each delivery length, this is confirmed by the test reports for every order.

Quality control system at all-production stages allows ensuring a continuous monitoring of cable quality and of the efficiency of promptly taking preventive measures for the quality improvement.

Estralin has certificates which state that their quality control system complies with requirements of ISO standard ISO 9001:2015, ISO 14000:2015, ISO 45001:2018.

The company offers a range of products for extra high-voltage cable systems 300-500 kV.

For more information of the product range, please contact us info@estralin.com